Confectionery

Achieve the perfect pucker in a sour candy or balance the sweet side of a sanded gummy with the right sour bite. Bartek’s malic acid imparts a fruit-like sourness with a desirable linger while our fumaric acid helps extend the sour and enhances the overall taste. In bringing these two specialty ingredients together, confectioners find their sweet spot.

Learn about our proprietary pectin-based gummy ingredient:

Applications

Gummies

The gummy is a trending format not only in confections, but also as a delivery system for nutritional supplements. For both candy gummies and gummy supplements, fruit and tropical flavors are popular. To make these flavors stand out and to prevent changes in flavor and texture from sucrose inversion, an acidulant is usually added to formulations. This is where malic acid by Bartek comes in handy.

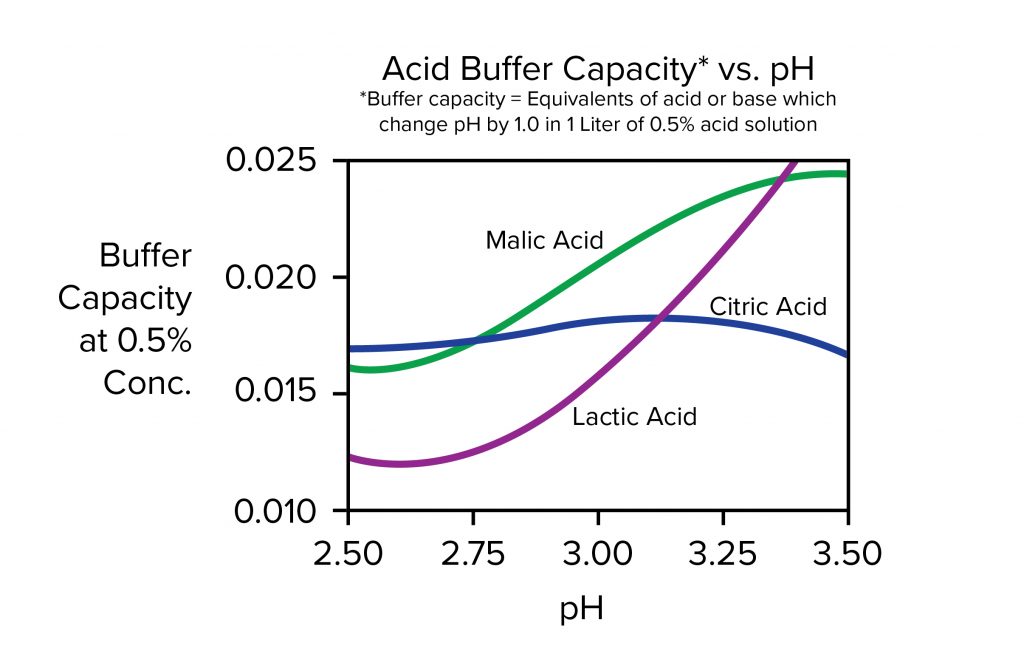

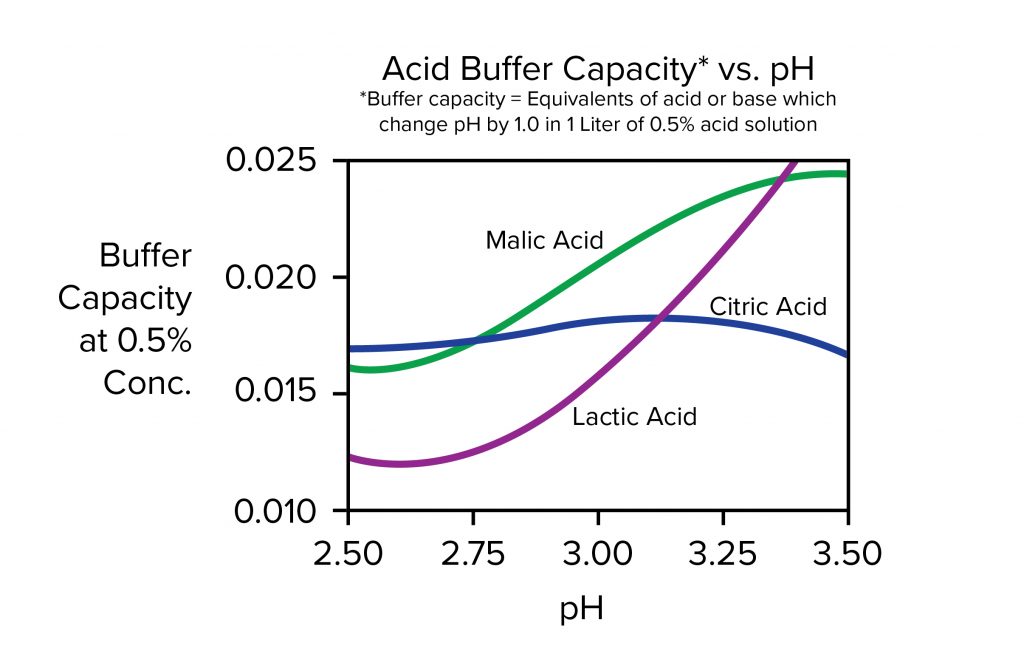

Most pectin-based gels have a pH of, or around 3.2, which is the range at which malic acid provides better buffering capacity than citric acid and other acidulants. Better buffering means better protection against inversion and acid hydrolysis of gelling agents. Also, malic acid complemented by sodium citrate (buffer) as a mismatched organic acid salt for improved pH control against sucrose inversion. The result is extended shelf life for chewy candies, more economical packaging alternatives, and a more enjoyable experience for consumers.

Gummies formulated with malic acid, as opposed to citric acid alone, are more stable in texture and flavor. Furthermore, malic acid outperforms citric acid in extending sour notes in gummy applications. This lingering sourness balances and smooths flavors, creating a more natural-tasting experience which is “true-to fruit.”

Furthermore, blending different acids with sweeteners will yield different sourness and flavor profiles. For example, blends of citric and malic acids can provide a more authentic basic sour taste to enhance fruit flavored gummies. Incorporate malic acid by Bartek at the end of the process to keep the gel stable and minimize changes in sucrose composition over time.

Applications

Chewy Candies

No matter your age, nothing delights like the soft textures and bright flavors of chewy candies. Whether it’s a fruity taffy or a candy-coated bite-sized confection, chewy candies are enjoyed by everyone, young and old. For the formulator, optimizing chewy candy for shelf life means stabilizing the texture and flavor.

When the pH of an application is close to 3.2, the acidity of most pectin-based gels, malic acid from Bartek provides better buffering capacity than citric acid and other acidulants. Moreover, malic acid minimizes sucrose inversion and acid hydrolysis of gelling agents. Also, malic acid complemented by sodium citrate (buffer) as a mismatched organic acid salt for improved pH control against sucrose inversion. The result is extended shelf life for chewy candies, more economical packaging alternatives, and a more enjoyable experience for consumers.

In addition to extending shelf life, malic acid extends the flavor profile of chewy candies. Since it lasts longer on the tongue than citric acid, malic acid prolongs the stimulation of the consumer’s taste receptors, creating a smoother, longer lasting flavor experience, which is “true-to fruit.” Use it to blend fruity flavors, citrus notes, and sweet floral aromatics.

Furthermore, blends of citric and malic acids are able to provide more authentic basic sour taste to enhance fruit flavored chewy candies.

In sugar/acid-coated candies, fumaric acid by Bartek is also useful for extending shelf life. Fumaric acid does not absorb moisture during storage and distribution. By keeping moisture levels low, fumaric acid impedes sucrose inversion. Mix it with sanding sugar to take advantage of these benefits.

Possibilities Include:

- Fruit-flavored taffies

- Sour chews

- Tropical flavors

- Bite-sized coated chewy candies

- Natural and artificial flavors

Applications

Hard Candies

The sweet satisfaction of hard candies is their ability to melt on the tongue, releasing tasty and enduring flavors that lingers on the palate. The key to creating an optimal hard candy experience is to balance these long-lasting flavors. To this end, sour notes from acidulants can stimulate salivation and bring out the character of fruity flavorings.

In order to maximize the life of the flavor experience, formulators need an acidulant that does not quickly dissolve in the mouth. While the sour effect of citric acid can be short-lived, malic acid from Bartek has a long-lasting tartness that prolongs fruity flavors in hard candy applications.

The persisting sourness of malic acid extends well beyond that of citric acid and activates a consumer’s taste buds over a longer period of time. Malic acid is also an effective flavor blender, which gives the flavorist more options by allowing for a wide range of unique and fruity combinations.

Furthermore, malic acid’s hydrophobic chemistry makes it effective at preventing sucrose inversion in hard candies which can result in sticky and unappetizing candy surfaces. When sucrose converts to other sugars over time, the taste and texture of an application can also change. Adding malic acid to an application extends shelf life by resisting this naturally occurring process in hard candy.

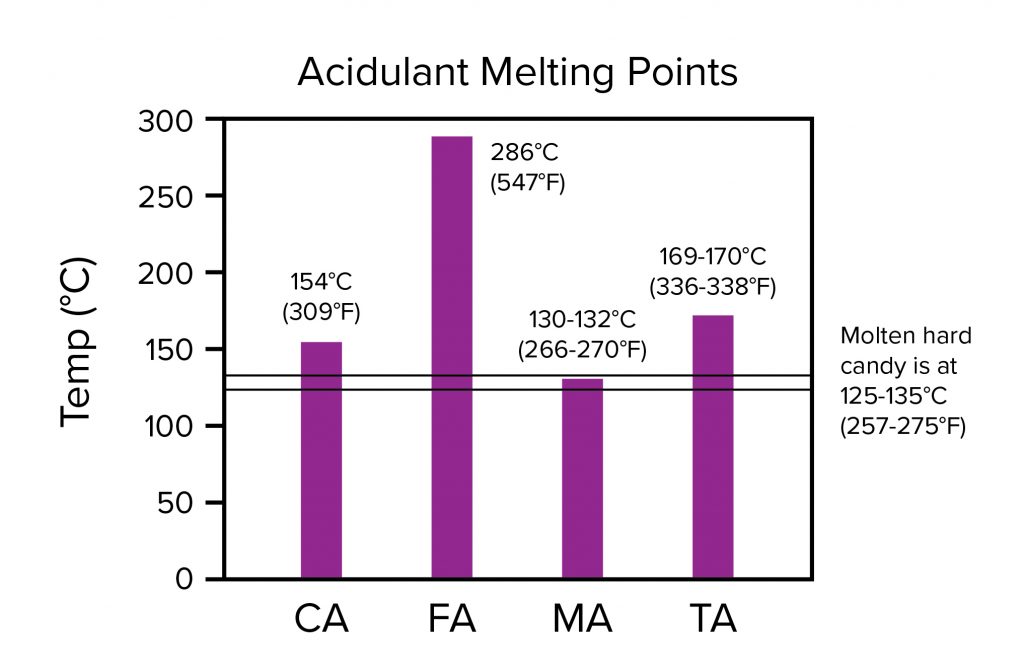

Sucrose inversion results in undesirable and sticky hard candy. Using granular malic acid instead of an acid solution results in a lower final moisture level in the hard candy. This hampers sucrose inversion and consequently extends shelf life. Malic acid can be used because of its lower melting point. A lower melting points means that it dissolves completely and quickly in the molten hard candy.

Possibilities Include:

- Lollipops

- Candy drops

- Candy rolls

- Candy canes

- Fruit flashers

- Individually wrapped hard candies

- Lozenges and cough drops

Applications

Chewing Gum

A good chewing gum should provide immediately intense flavor followed by sustained refreshment. The burst of flavor from the first chew of a stick of gum should be delightful and memorable. However, if that flavor dissipates in a matter of seconds, the gum becomes bland and uninteresting.

Malic acid by Bartek blends and extends flavors in chewing gum to build a lasting, memorable, experience. Since it produces a longer-lasting sourness than citric acid, malic acid stimulates more salivation and allows for an extended sensation of juiciness.

Bartek’s malic acid works well with fruity and minty flavors. In sugar-free chewing gums, malic acid matches the prolonged effect of high-intensity sweeteners, resulting in a flavor profile that is long and balanced. To take advantage of these benefits, incorporate malic acid during the kneading of the gum base or use powdered malic acid to dust the finished gum.

Possibilities Include:

- Fruit-flavored chewing gum

- Mint-flavored chewing gum

- Sugar-free applications

Applications

Sugar Free (“Clean-Label”)

The movement toward new regulations is only just beginning. Health systems will be unable to cope with the strain of diseases caused by obesity and diabetes, leading governments to intervene more strongly to curb intake of sugar and fats. Food manufacturers will have to comply the new regulations. However, taste is the most important factor in consumer’s purchasing decisions. High-intensity sweeteners outlast other flavors in low-calorie confections, resulting in a lingering taste that is unbalanced and unappetizing.

A touch of tanginess smooths out the sweet bite of high intensity sweeteners and other sugar substitutes. However, commonly used acidulants, such as citric acid, have a short-lived sour. Once it dissipates, the acute sweetness of low-calorie sweeteners overpowers applications.

Luckily, malic acid by Bartek solves the problem of formulating with sugar substitutes. The extended sourness of malic acid matches the persistent sweetness of the low-calorie alternatives. The sour zest of malic acid lasts over twice as long as citric acid. When combined with sugar substitutes, the enduring tartness of malic acid creates a smoother and more satisfying flavor profile when compared to other acidulants.

In candies, add malic acid at the end of the production process to minimize exposure to high temperatures. In chewing gums, knead it into the gum base or use powdered malic acid to dust the finished product.

Possibilities Include:

- Sugar-free hard candy

- Sugar-free chewy candy and gummies

- Sugar-free chewing gum

- Low-calorie snack confections

- Low-calorie compressed candy tablets